Ultimate Guide to Stainless Hex Nuts Tips for Your Projects?

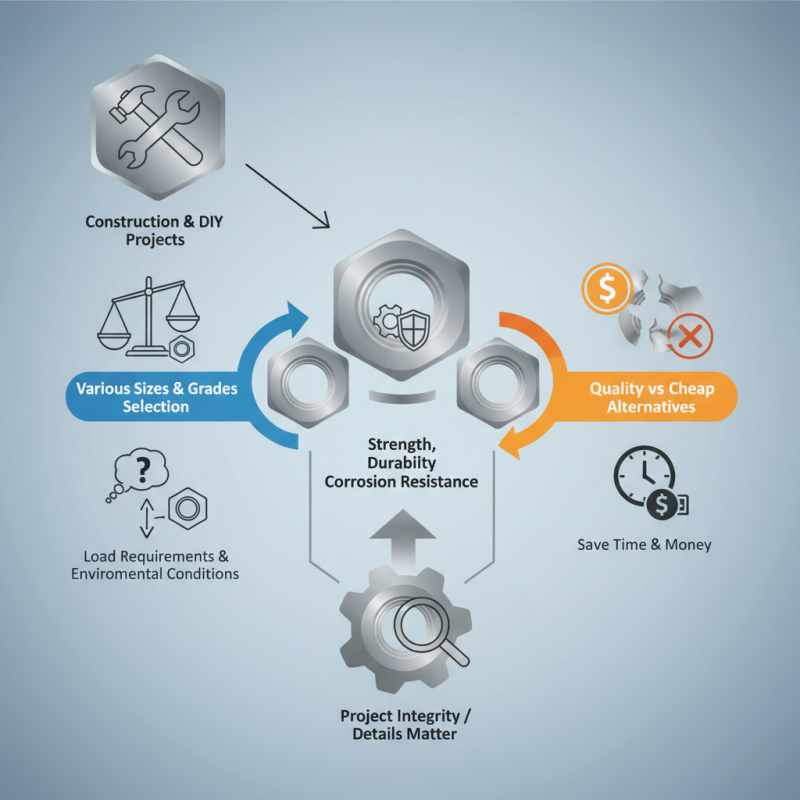

When it comes to construction and DIY projects, choosing the right materials is essential. Stainless Hex Nuts are a vital component in this realm. They provide strength, durability, and resistance to corrosion. Understanding their applications can greatly enhance your projects.

Stainless hex nuts come in various sizes and grades. This variety can lead to confusion. It is crucial to select the correct type for each specific situation. The right choice affects the overall integrity of your work. Think carefully about factors like load requirements and environmental conditions.

Many people overlook the importance of quality. Cheap alternatives may seem appealing, but they often result in failures. Investing in high-quality stainless hex nuts can save time and money in the long run. Consider this when planning your next project. Each detail counts, and the right hardware makes a difference.

Understanding Stainless Hex Nuts: Types and Specifications

When working on various projects, understanding stainless hex nuts is essential. These fasteners come in many types, like regular hex nuts and lock nuts. Regular hex nuts are often used for standard applications. Lock nuts, however, can prevent loosening over time. Choosing the correct type is crucial for project durability.

Specifications also vary among stainless hex nuts. They are rated based on their tensile strength and corrosion resistance. Common grades include 304 and 316. Grade 304 offers good corrosion resistance but may not perform well in saline environments. Grade 316, on the other hand, is better suited for marine applications. Knowing these specifications helps in selecting the right nut for the right environment.

Consider compatibility with bolts as well. Mismatched sizes can lead to weak connections. Always double-check measurements before finalizing your choice. Some projects even require unique threading or finishes. If you overlook these details, it may lead to frustrations down the road. It’s vital to strike a balance between quality and cost when choosing these essentials.

Understanding Stainless Hex Nuts: Types and Specifications

Key Applications of Stainless Hex Nuts in Various Industries

Stainless hex nuts are vital components in various industries. They offer corrosion resistance, strength, and durability, making them ideal for challenging environments. According to a report by MarketsandMarkets, the global stainless steel fasteners market is expected to reach $20.2 billion by 2025. This growth highlights the increasing demand in sectors like construction, automotive, and manufacturing.

In construction, stainless hex nuts are commonly used in structural applications. They secure beams and frames, ensuring stability under load. The automotive industry relies on these fasteners for critical components, enhancing vehicle safety and performance. A study from Research and Markets indicates that the automotive fastener market will grow by 4.2% annually, driven by rising vehicle production.

While stainless hex nuts are robust, not every project benefits from their use. In applications with low load demands, using less expensive materials might be more practical. Additionally, misalignment during installation can lead to failures. It’s essential to choose the right nut for the job and monitor their performance over time. The selection process should involve considering factors like environmental exposure and mechanical requirements.

Choosing the Right Stainless Hex Nut for Your Project Needs

When selecting stainless hex nuts for your project, several factors come into play. The most crucial aspect is determining the size. Hex nuts come in various dimensions, and choosing the wrong size can lead to significant issues. Measure your bolts carefully. A mismatch can cause weak connections, leading to failures.

Material choice is another key consideration. Stainless steel hex nuts resist corrosion, making them ideal for outdoor projects. They maintain integrity over time. However, not all stainless steels are equal. Understanding grades like 304 and 316 can impact your choice. Grade 316 is superior in marine environments, while 304 is often sufficient for general use.

Be mindful of the thread type as well. Coarse threads are easier to install, while fine threads offer more holding strength. The right choice can affect assembly time and durability. Testing different options on smaller projects can provide insights. Drawing a comparison between what works and what doesn’t may lead to unexpected learnings. Creating a balance between quality and cost is another challenge.

Ultimate Guide to Stainless Hex Nuts Tips for Your Projects

| Nut Size | Material Grade | Finish Type | Load Capacity (lbs) | Common Applications |

|---|---|---|---|---|

| 1/4" | A2 | Plain | 800 | Electrical Equipment |

| 5/16" | A4 | Zinc Plated | 1000 | Marine Applications |

| 3/8" | A2 | Electrolytic Nickel | 1200 | Heavy Machinery |

| 1/2" | A4 | Passivated | 1500 | Construction |

| 5/8" | A2 | Polished | 2500 | Automotive |

Installation Tips and Techniques for Stainless Hex Nuts

When working with stainless hex nuts, proper installation techniques can significantly affect your project’s durability. Begin by choosing the right washer for your nut. Flat washers distribute load evenly, while lock washers prevent loosening. Ensure the bolt is clean and free of debris. Dirt can compromise the connection and lead to failure. A small effort to clean can save a lot of trouble later.

When tightening, use a calibrated torque wrench. It is crucial to follow the manufacturer’s specifications. Over-tightening can damage the nut and bolt. Under-tightening may result in loosening during operation. Sometimes, it’s wise to make a practice run on a scrap piece. This helps gauge the right tension. Don’t overlook the importance of using anti-seize lubricant in corrosive environments. It aids in easy disassembly later.

Remember, installation can be tricky. Sometimes, a seemingly minor mistake can lead to larger issues. Check each connection after installation. This step is easy but often skipped. Keeping a checklist can keep you organized. Each component plays a vital role in the overall strength of your project. Pay attention to details, and always reassess your approach if something feels off.

Maintenance and Care for Stainless Hex Nuts to Ensure Longevity

Maintaining stainless hex nuts is crucial for long-lasting performance. Regularly check for signs of wear or corrosion. Even stainless steel can rust under certain conditions. It’s essential to keep the nuts clean and dry. Use a soft cloth to wipe off dirt and moisture. A little effort goes a long way in prevention.

Consider storing hex nuts in a dedicated container. This avoids unnecessary exposure to the elements. If you notice a nut has lost its finish, don't ignore it. Replace it promptly to prevent further issues. Avoid over-tightening, as this can damage both the nut and the bolt. Proper torque is key.

While these tips may seem basic, many overlook them. Sloppy storage can lead to mixed sizes and loss of parts. Even small mistakes can cause project delays. Be mindful of your practices. Reflect on how these simple steps impact overall project success. A little care in maintenance pays off in durability.